WHAT IS 5S AND 5S BENEFITS?

5S management system

What is 5S?

1 know about 5S safety system

2 Discuss about essential elements housekeeping

3 Discuss about good housekeeping practices

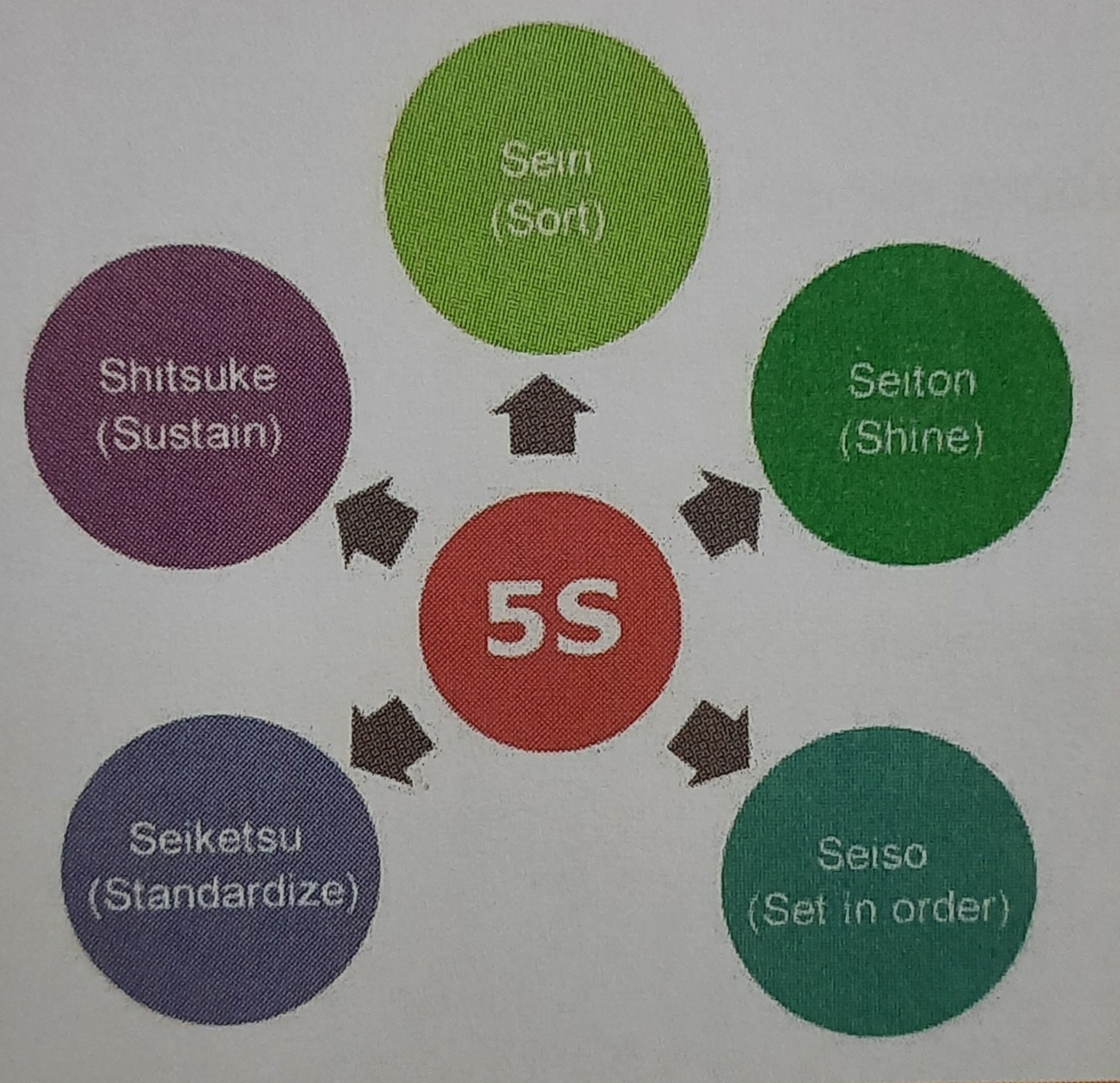

5s is a fundamental systematic basic approach for quality productivity and safety improvement. 5S (Japanese philosophy )is the name of a workplace organisation procedure. 5S is created by a list of 5 Japanese words seiri, seiton, seiso, seiketsu, and shitsuke. 5S system is implemented for organizing the workplace for increasing effectiveness and efficiency by maintaining the area and items storing the items used and staining the new practices.

Objectives of 5S

The manufacturing process to be standardise

Focus on safety and health

Production can be increase by the use of 5S

By 5S the quality of products and service is improve

Tools can be search in very less time

PHASES OF 5S:

1.Seiri(Sort)-Do work simply by removing obstructions

Stop build up of needless things

Remove all parts not in use

Waste removal

Define a red tagged area to keep unnecessary items

Skilled supervisor is requiring for checking on regular basis

Separate unwanted items from the workplace.

2.Seiton (Set in order)- For items to be easily available arrange them all properly

Make simple to identify and pick up essential things

Make simply to identify and pickup essential things

Work on first come and first services method

All work should be complete on regular basis

This makes the work flow easy and smooth

3.Seiso (Shine)- keep workplace safe

Workplace should be completely clean and clear

Stop weakening of machinery and equipment

Keep workplace clean and shine

If someone isn't familiar to the environment must be able to find problems in 5 seconds within 50 feet.

4.Seiketsu (Standardize) -everything is its right place

Every process has standard

Keep high standards at workplace organisation at all times

Keep neatness keep everything in order and according to its standard

5.Shitsuke (Sustain)- to maintain in working order

Also translates as do without being told

Regular audits to be perform

Discipline and training

Advantages of 5s

If equipment and tools are are properly placed in organized work areasItems can be visible very easily

It leads to greater workstation efficiency and mass production

To greater will being amplify motivation workplace should be clean and tidy

Time saving

Increases work space

Smooth working no obstruction

Minimization in mistakes and accidents

5s Audit

Purposes of conducting regular 5S audits are :

Evaluation of 5S standards for industry

To fix what is wrong note and address non compliance

Give a official chance to suggest improvements

The Basic Steps:

Plan for the audit divide the workplace into service areas for successful audit reviews

Based on the standard set during audit make a list of every area find out the list of non problems in each area from the initial 5S sweep this may include:

Rack of tool

Need of repairing machines

Equipment and materials which were not cleared instantly

Three key tasks has to be done during the audit:

1. Find out whether non difficulties have been addressed

Lubricants are still leak from this machine?

People are not working under crane, is the warning sign in place ?

Why outdated drill press in still in the workshop?

2. Look into the standards is being met:

Are tool left on work tables?

From the tool rack is something?

Is dirt collecting anywhere?

Are safety levels visible and readable?

3. To be noted that what has not yet been standardizedWhy is there no sign over the well ordered stack of work in process materials on that shelf?

Tools that are not yet labeled.

5s Audit form👇

If you want to learn cnc programming and industrial instruments with practical so click on below given link and subscribe my you tube channel.

Subscribe My Youtube Channel - Click Here

If you want to see 5s video with practical so please click on below 5s practical video link in this video we performed a practical through example of sorting,Set in order,shine, standardize,and sustain so this video watch this video for better understanding.

TO SEE 5S PRACTICAL VIDEO-5S PRACTICAL VIDEO

Very use full information thanks

ReplyDelete